Sound insulation and soundproofing of machines – create a quieter and more efficient working environment

Soundproofing and sound dampening machines is crucial for reducing noise levels, improving the working environment, and protecting both people and machinery. High noise levels from machines such as motors, compressors, pumps, and industrial tools can have a negative impact on productivity, concentration, and health. By using the right sound-absorbing materials and vibration-damping solutions, noise can be significantly reduced, resulting in a safer and more comfortable working environment.

In addition to the working environment benefits, effective sound insulation can also reduce wear and tear on machinery, improve energy efficiency, and ensure that the business complies with applicable working environment regulations. By taking control of noise levels, companies can create a better workplace while avoiding legal and financial problems associated with high noise levels.

Why is soundproofing machinery important?

Noise from machines is mainly generated by mechanical vibrations, airborne noise, and structure-borne noise. If the noise is not managed properly, it can spread throughout the premises and create a noisy working environment that negatively affects both employees and machines.

Some of the most common problems associated with machine noise include:

Hearing damage and health problems

Prolonged exposure to high noise levels can cause hearing damage, stress, and fatigue.

Reduced productivity

Noise makes it difficult to concentrate, leading to impaired work performance and more mistakes.

Increased wear and tear on machinery

Strong vibrations can cause mechanical damage and lead to higher maintenance costs.

Legal requirements and work environment regulations

Many countries have strict rules regarding noise levels in the workplace.

By implementing the right noise reduction measures, these problems can be minimized, leading to a better working environment, lower maintenance costs, and higher efficiency.

Effective methods for soundproofing and soundproofing machines

To achieve the best possible noise reduction, a combination of sound-absorbing and vibration-damping materials is required.

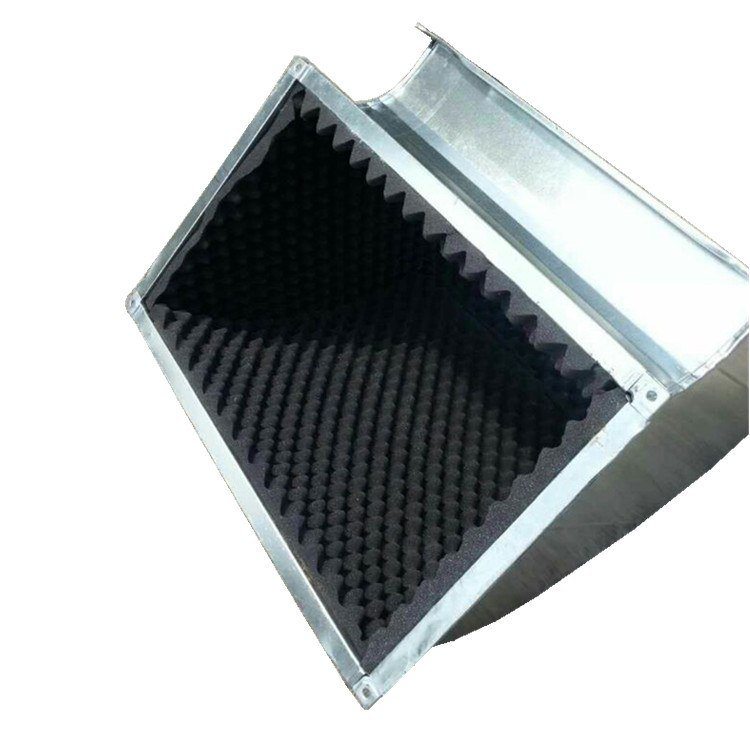

1. Sound-absorbing panels and acoustic materials

By installing sound-absorbing panels near the machine, sound waves can be captured and dampened before they spread throughout the room. Examples of effective materials include:

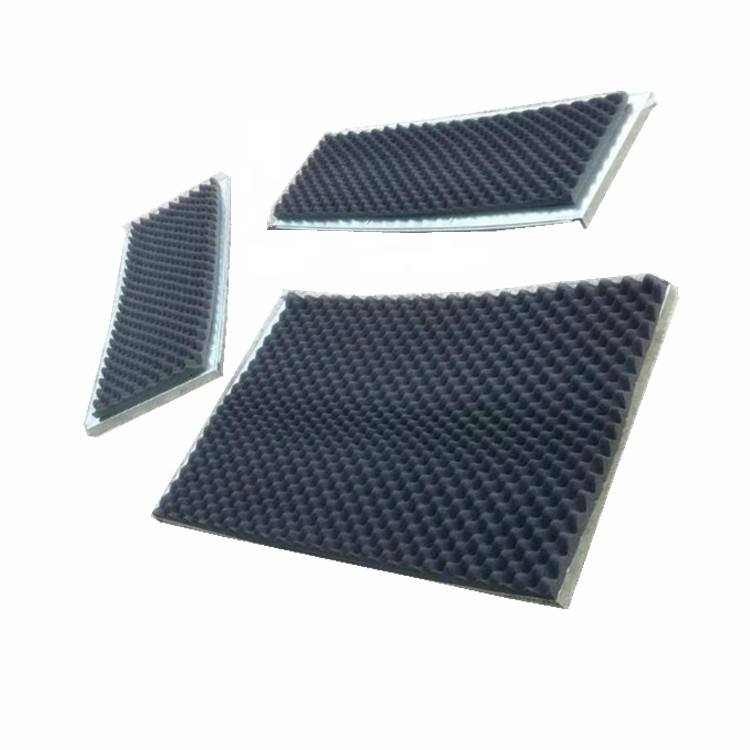

- SilentDirect Egg – A high-performance sound absorber with a textured surface for maximum noise reduction.

- Mineral wool and polyester fiber – Perfect for reducing both low-frequency and high-frequency sounds.

- Acoustic foam – Effective at absorbing high-frequency sounds and reducing reverberation.

By applying these materials to walls, ceilings, and around machinery, the noise level can be significantly reduced.

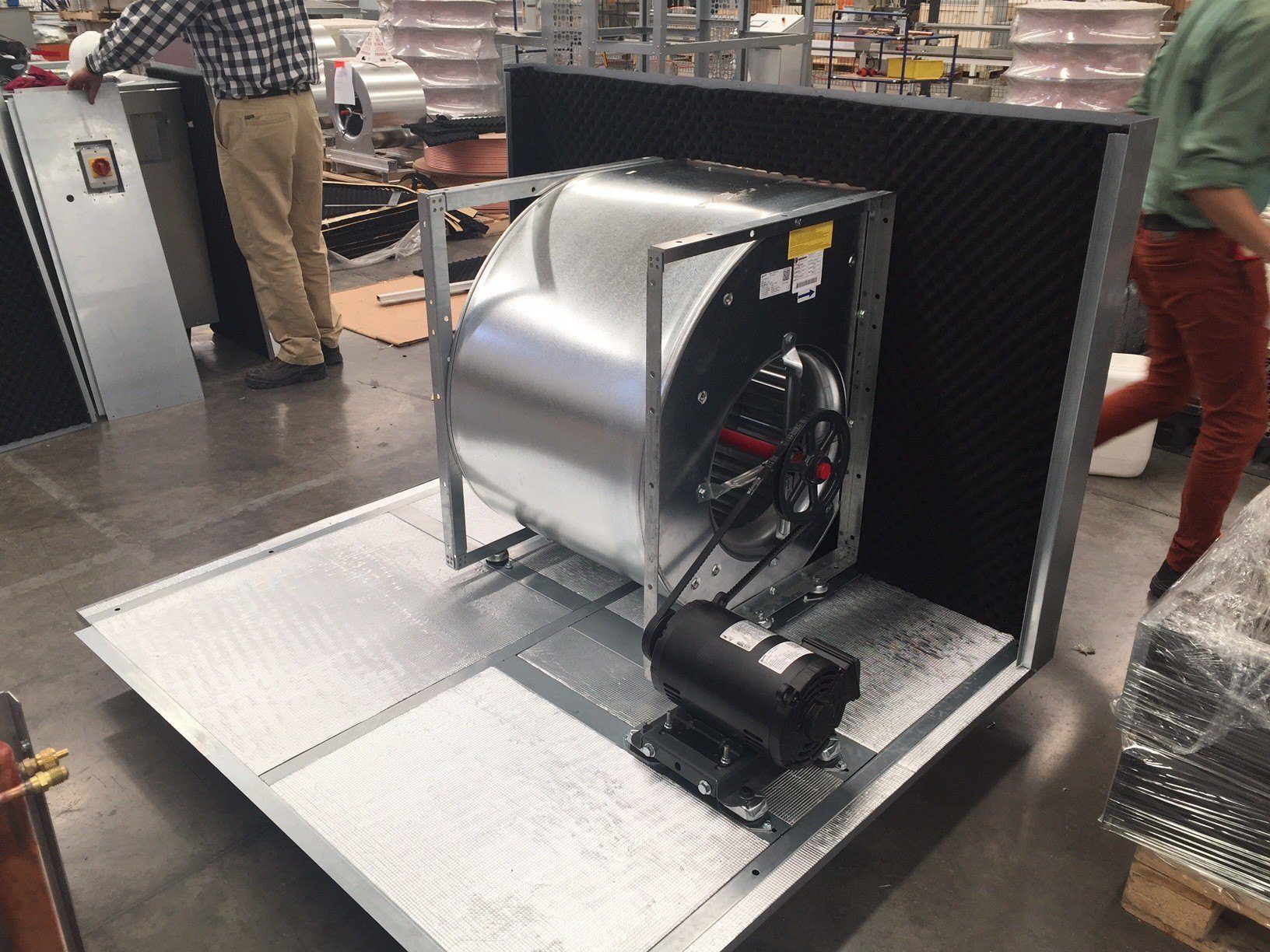

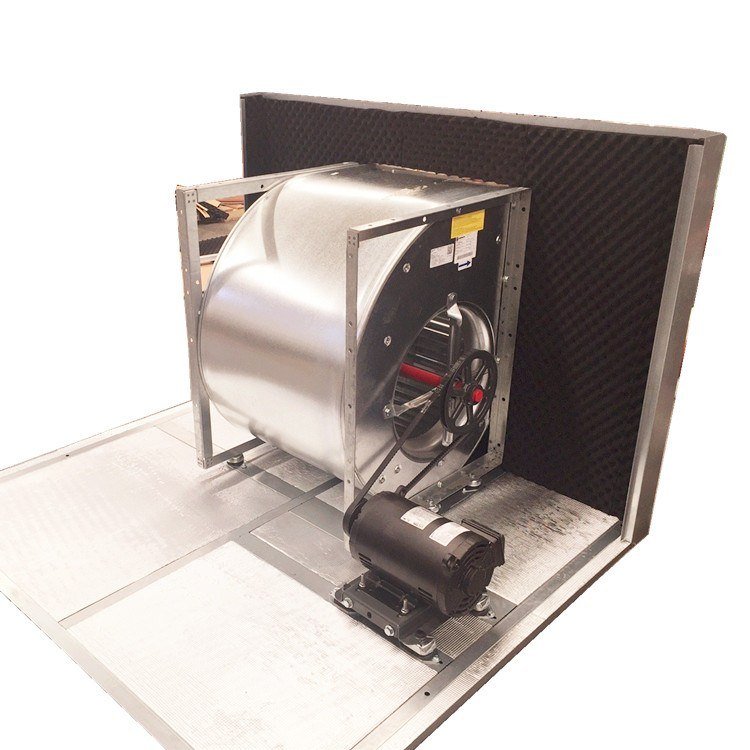

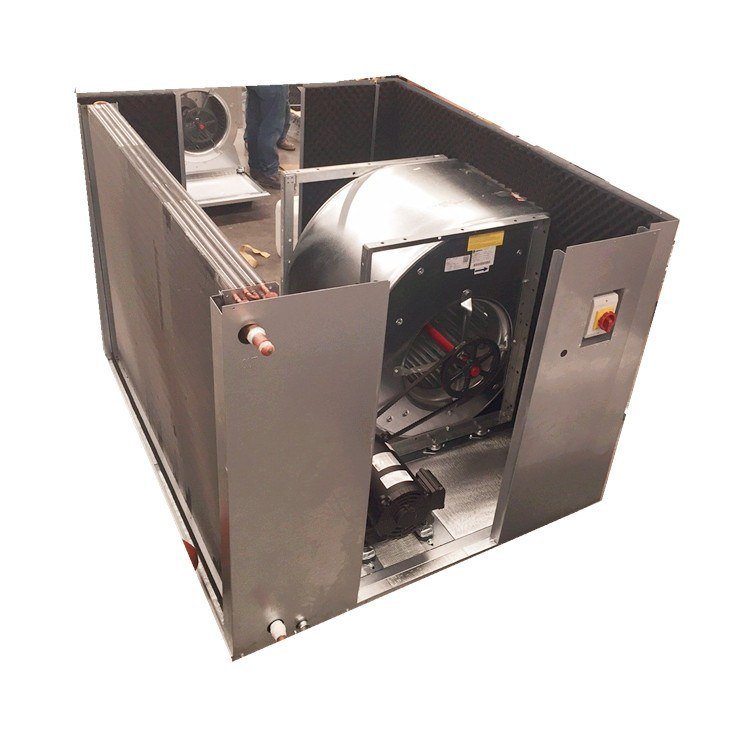

2. Enclosures and sound-insulating hoods

Building sound-insulating enclosures around noisy machines is one of the most effective solutions for reducing noise propagation. These can be constructed using:

- SilentDirect Polaric or MLV (Mass Loaded Vinyl) to maximize sound insulation.

- Multi-layer materials that combine sound insulation and sound absorption.

- Ventilated silencers that ensure the machine is adequately cooled without the sound escaping.

Enclosures not only reduce noise but also protect the machine from dust and external influences.

3. Vibration damping to reduce structure-borne noise

Vibrations from machines can be transmitted to floors, walls, and ceilings, creating a deep and disturbing noise. To eliminate this, you should use:

SilentDirect Vibration dampers

A proven solution for minimizing sound transmission from machines.

Rubber mats and vibration damping plates

Effective for reducing the transmission of vibrations to the substrate.

Suspension mounts and isolators

To separate the machine from the floor and reduce structure-borne noise.

These measures prevent sound from propagating through the building structure and contribute to a significantly quieter working environment.

The benefits of soundproofing machines

By investing in noise reduction measures, companies can achieve several important benefits:

Better working environment

Reduced noise levels create a more pleasant and productive workplace.

Longer machine life

Less vibration and mechanical stress leads to fewer repairs and lower maintenance costs.

Increased energy efficiency

Machines that generate less noise and vibration often consume less energy.

Compliance with legal requirements

Reducing noise levels ensures that the company complies with the Swedish Work Environment Authority's regulations.

Reduced disturbance to the surrounding area

Noise reduction contributes to better relations with neighbors and reduces the risk of complaints.

How do you choose the right soundproofing solution?

When choosing soundproofing measures, it is important to consider:

1. Type of machine and noise level – Is it high-frequency or low-frequency noise? Do you need sound insulation or vibration damping?

2. Surroundings and working environment – Do you need sound-absorbing panels on the walls or complete enclosure around the machine?

3. Laws and regulations – Ensure that your soundproofing meets the Swedish Work Environment Authority's requirements for noise levels.

By combining the right soundproofing materials with smart installations, you can ensure effective and long-term noise reduction.