Soundproofing and sound insulation for machines – Effective solutions for a quieter working environment

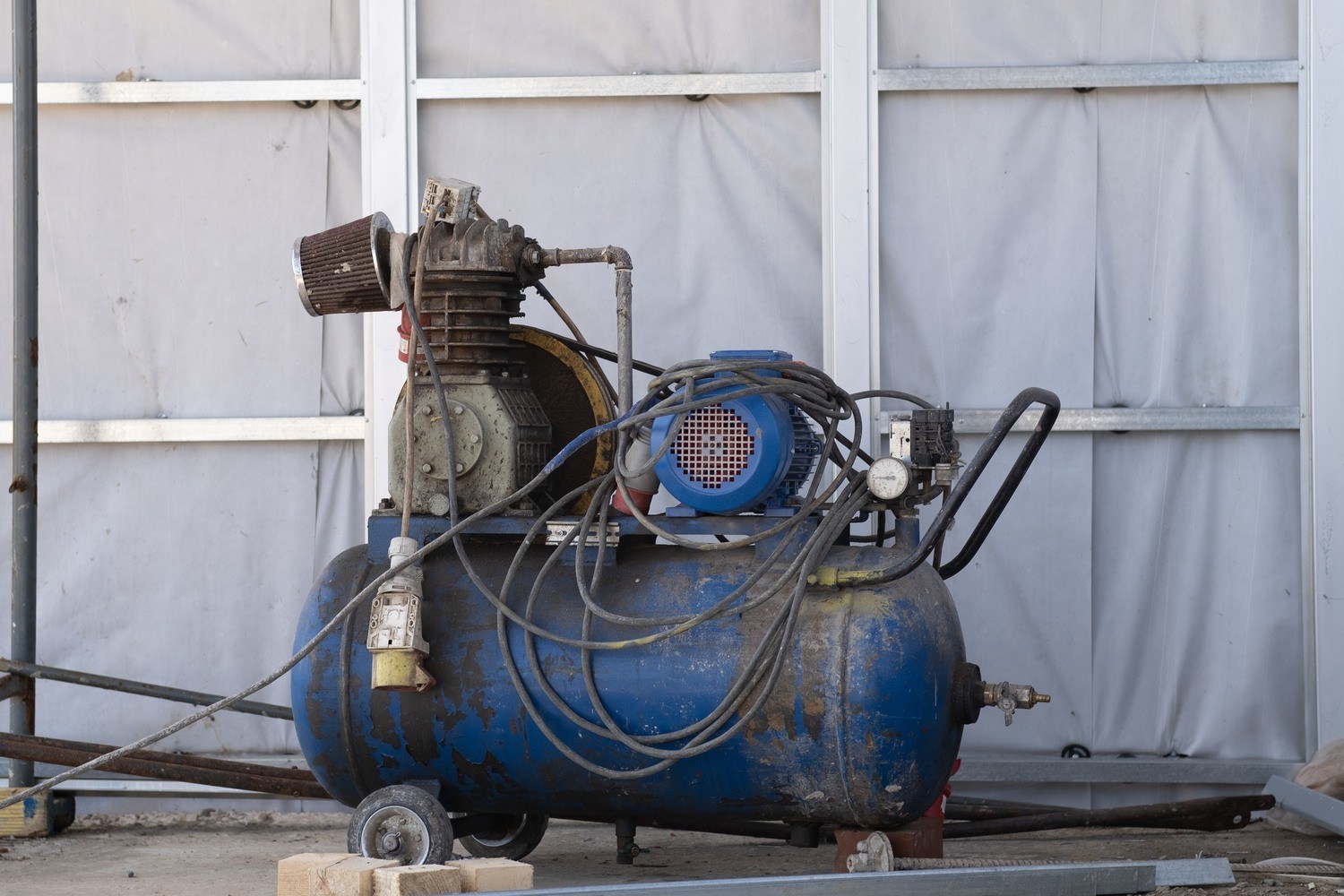

Soundproofing and noise insulation for machines is crucial for reducing noise levels, improving the working environment, and complying with applicable occupational health and safety requirements. Many machines, such as compressors, fans, generators, and industrial machinery, generate high noise levels that can be disruptive and potentially harmful to both staff and the surrounding environment.

By using the right soundproofing measures, you can reduce noise, prevent sound propagation, and create a more productive and pleasant workplace. Here we go through the most effective methods for dampening and insulating machine noise.

How does noise from machines arise?

To effectively dampen sound, you must first understand the type of sound the machine generates. Machine noise can be divided into two main categories:

Airborne noise

Spreads through the air and is generated, for example, by engines, fans, and exhaust fumes.

Structure-borne noise (vibration noise)

Occurs when the machine generates vibrations that propagate through floors, walls, and other surfaces.

Depending on the type of noise the machine generates, different soundproofing techniques need to be combined to achieve the best possible results.

Effective methods for soundproofing and soundproofing machines

To create a quieter working environment, a combination of sound insulation, sound absorption, and vibration damping should be used.

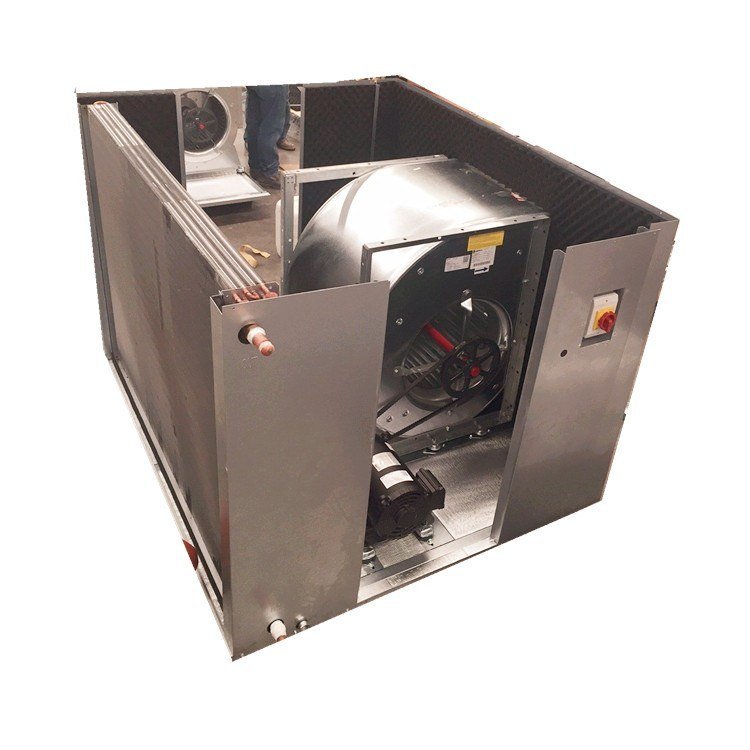

Sound-insulating enclosures – Reduction of airborne noise

One of the most effective methods for reducing machine noise is to build a sound-insulating enclosure around the machine. A properly designed enclosure can reduce the noise level by up to 20–40 dB, which makes a big difference in the working environment.

Vibration damping – Stop noise at the source

Machines often generate vibrations that spread through floors, walls, and other surfaces, which can amplify the noise. These measures help to stop the vibrations at the source and prevent them from propagating throughout the building.

Acoustic barriers and sound absorption in the room

If the noise spreads throughout the room, acoustic barriers and sound-absorbing materials can help dampen sound waves and reduce reverberation. These measures contribute to a more pleasant working environment and make the sound seem significantly lower.

Optimize machine placement for better noise control

The location of the machine has a major impact on how noise spreads. To minimize disturbances, you can:

- Place noisy machines in separate rooms to isolate the sound.

- Use sound barriers between the machine and the work area.

- Avoid placing machines near walls or corners, as sound waves can easily be reflected and amplified.

By thinking strategically about the location of the machine, you can reduce the need for extensive noise reduction measures.

Preventive measures – Maintenance and noise reduction technology

Regular maintenance of machines can help reduce noise levels by:

- Replacing worn components that can cause extra vibration and noise.

- Ensuring that the machine is properly adjusted and that all parts are correctly fastened.

- Using modern machines with built-in noise reduction, which can be a long-term solution.

By combining the right noise reduction measures with ongoing maintenance, you can create a quieter and more sustainable working environment.