Soundproof and insulate your laundry room – How to create a quieter environment

A laundry room is one of the places in the home where noise can be most noticeable. Washing machines and dryers generate both airborne noise and structure-borne noise, which can spread through walls, floors, and ceilings and cause disturbances in nearby rooms. This is particularly problematic in homes where the laundry room is located near bedrooms, living rooms, or studies, where a quiet sound environment is crucial for comfort and well-being.

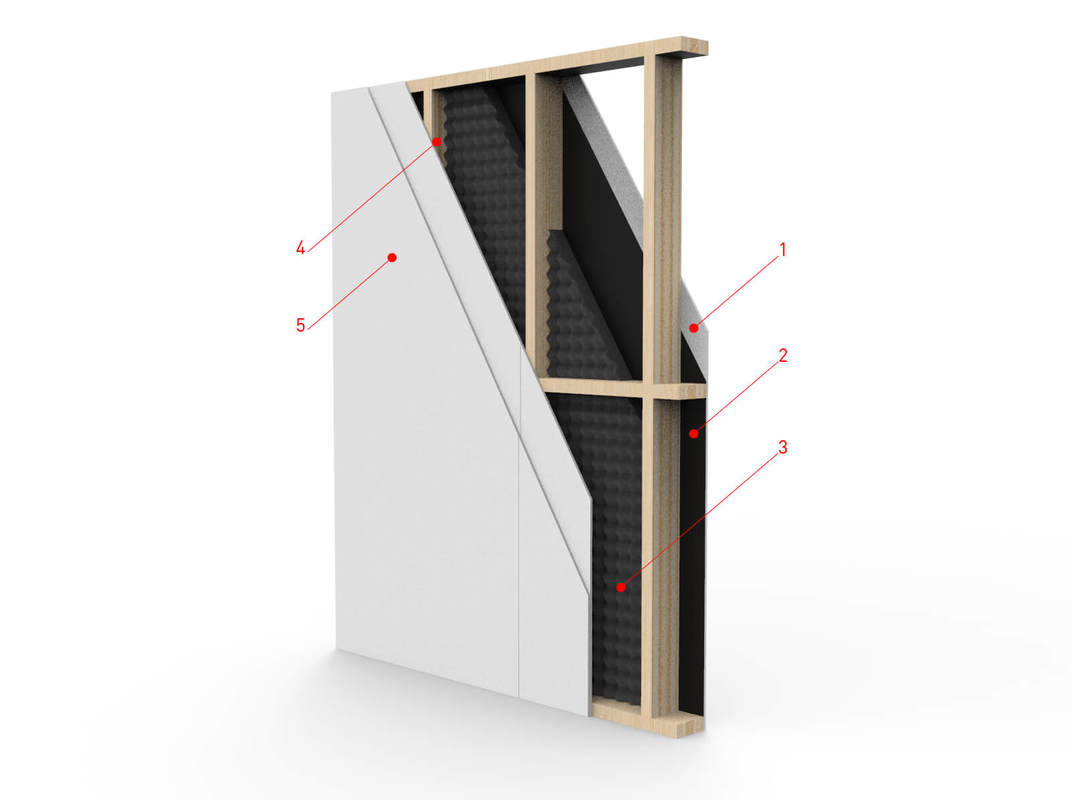

Soundproofing and insulating a laundry room is not just about reducing noise in the room itself, but also about preventing sound from spreading to other parts of the home. By using sound-absorbing materials, vibration-damping solutions, and sound insulation techniques, you can create a quieter and more comfortable environment.

The difference between soundproofing and sound insulation

To effectively control the noise level in a laundry room, a combination of soundproofing and sound insulation is required.

Soundproofing involves reducing the noise level inside the laundry room by using materials that absorb sound and prevent sound waves from reflecting between hard surfaces.

Soundproofing aims to block sound from spreading to other rooms by reducing sound leakage through walls, floors, ceilings, doors, and vents.

For best results, these two methods should be combined so that noise is both absorbed and prevented from spreading.

Effective measures to reduce noise in the laundry room

To create a quieter and more pleasant sound environment in the laundry room, there are several important measures to take.

- Sound-absorbing materials on walls and ceilings

- Dampen structure-borne noise with vibration-damping underlay

- Soundproof doors and vents

- The importance of flooring for soundproofing

- Placement of machines and furniture for better sound control

Soundproofing for different types of laundry rooms

Whether you have a home laundry room, a communal laundry room in a condominium association, or a professional laundry facility, there are solutions that can be adapted to your needs:

In homes

The focus should be on reducing the noise level inside the room and preventing the noise from spreading to bedrooms and living rooms.

In multi-family buildings

It is important to minimize sound transmission through walls and floors so that neighbors are not disturbed.

In commercial laundries

A more comprehensive sound insulation solution is often required to handle both machine noise and vibrations.

How to create a quieter laundry room

Soundproofing and insulating a laundry room involves combining sound-absorbing materials, vibration-damping solutions, and sound blocking to create a better sound environment. The most important measures include:

- Sound-absorbing panels on walls and ceilings to reduce reverberation.

- Vibration-damping underlay and sound-insulating flooring to minimize structure-borne noise.

- Sealing strips and soundproof doors to prevent sound leakage.

- Smart placement of machines and furniture to reduce noise.