How do you build an effective vibration-damping disc?

Building a vibration-damping disc is a smart solution for reducing noise and vibrations from machines and equipment that can otherwise create disturbing sounds and damage to the surface. Vibrations from household appliances, exercise machines, speakers, and industrial equipment can spread through floors, walls, and other surfaces, leading to noise, resonance, and structure-borne sound. By using the right materials and construction techniques, you can create a panel that effectively absorbs and dampens vibrations, improving both the sound environment and stability.

How does a vibration-damping panel work?

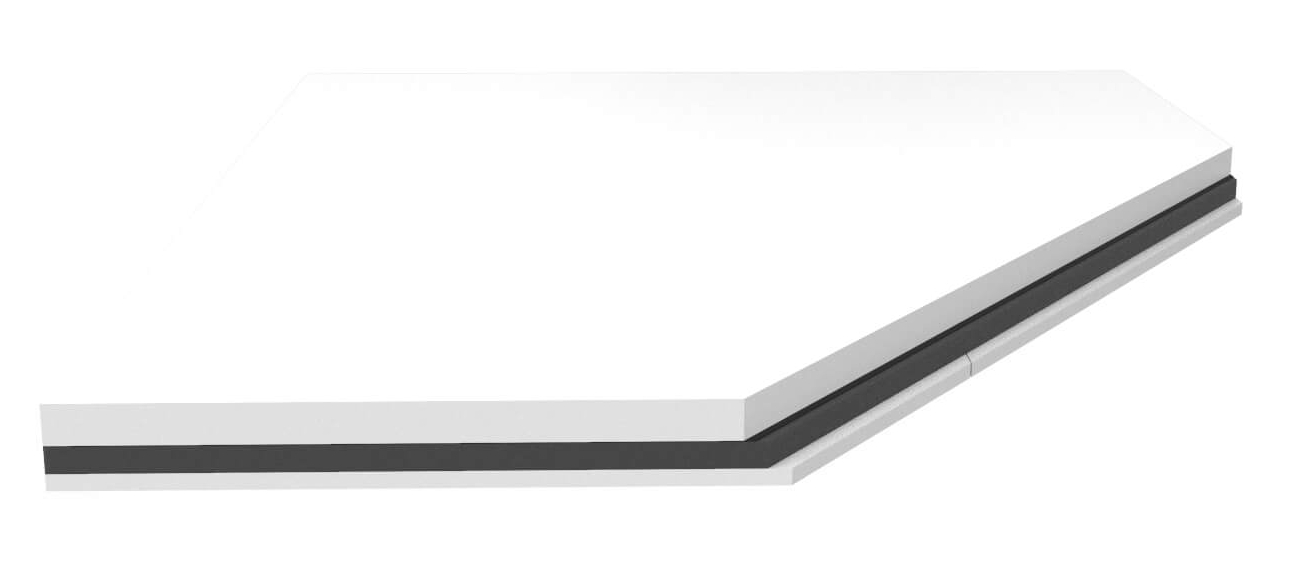

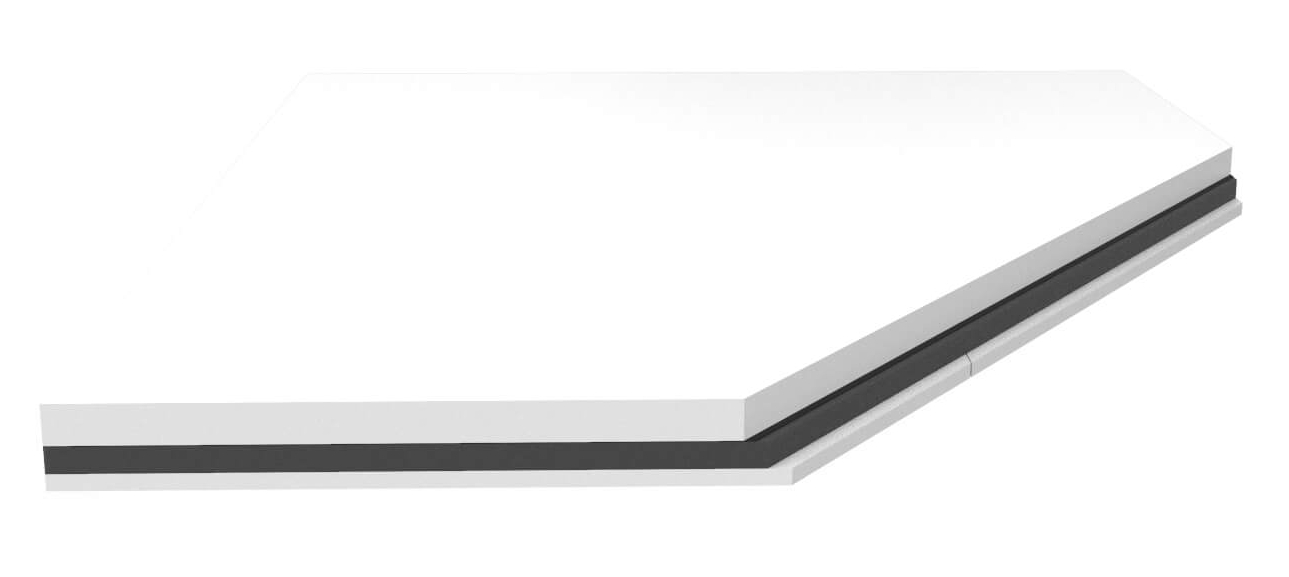

A vibration-damping panel works by combining materials with high density and elastic properties, which absorb and isolate vibrations from spreading further into the building. To achieve the best possible damping, it is important to use a multi-layer construction, where each layer fulfills a specific function.

The most important factors to consider in the design are:

Damping materials

Materials such as rubber, cork, or foam absorb vibrations and reduce resonance.

Stable core

A solid sheet of MDF, plywood, or wood provides weight and stability, which helps to reduce sound transmission.

Insulating base

A springy layer of, for example, nitrile rubber (NBR) can help prevent vibrations from propagating through the floor.

Applications for vibration-damping boards

Vibration-damping boards can be used in a variety of environments to reduce disturbing noise and vibrations.

Under household appliances

Washing machines and dryers generate powerful vibrations that can spread through the floor. A vibration-damping disc reduces this and protects the floor.

For exercise equipment

Treadmills, exercise bikes, and weightlifting equipment can cause vibrations that spread throughout the building. By placing a vibration-damping disc under the equipment, you can reduce both noise and floor wear.

Under speakers and music systems

Subwoofers and speakers can cause low-frequency vibrations that affect sound quality and spread to other rooms. A vibration-damping disc improves sound insulation and reduces resonance.

In industrial environments and workplaces

Machinery and production equipment often generate vibrations that can damage both equipment and building structures. A vibration-damping sheet can reduce wear and tear and improve the working environment.

How to build a vibration-damping panel

A vibration-damping panel is an effective solution for reducing vibrations and noise in both homes and work environments. For best results:

- Use several layers of material - Combine stable discs with damping materials such as rubber, cork, or foam.

- Ensure that the panel is heavy and stable enough to effectively absorb vibrations.

- Adapt the design as needed – Different machines and applications require different levels of damping.

- Place the sheet strategically to reduce sound propagation and improve acoustics.