Alternativ 1 – Det mest effektiva sättet att ljudisolera ett tak

Enligt vår erfarenhet är detta den mest effektiva metoden för att ljudisolera ett tak och skapa en tystare inomhusmiljö.

Innan du börjar

Innan du påbörjar arbetet med att ljudisolera ett tak är det viktigt att först analysera den befintliga konstruktionen. Inspektera taket noggrant och identifiera eventuella sprickor, fogar eller andra öppningar där ljud kan läcka igenom. Små springor kan ha en stor inverkan på ljudöverföringen och bör därför tätas ordentligt.

Använd lämpligt tätningsmedel, såsom akustisk fogmassa eller flexibel fogmassa, som effektivt blockerar ljudvågor och förhindrar att ljud tränger igenom svaga punkter. Det är också en god idé att undersöka om taket har några luftkanaler eller andra genomföringar som kan påverka ljudisoleringen och vid behov vidta åtgärder för att minska ljudläckage.

Det är viktigt att ha realistiska förväntningar – ett helt ljudtätt tak är svårt att uppnå, men genom att kombinera olika ljudisoleringsmetoder kan du avsevärt reducera ljudöverföringen. En effektiv strategi innefattar att kombinera ljudabsorberande material, tunga skikt som dämpar vibrationer och fjädrande upphängningar som minskar ljudets spridning genom byggnadens struktur. Genom att noggrant förbereda taket innan du går vidare till nästa steg säkerställer du att ljudisoleringen blir så effektiv som möjligt.

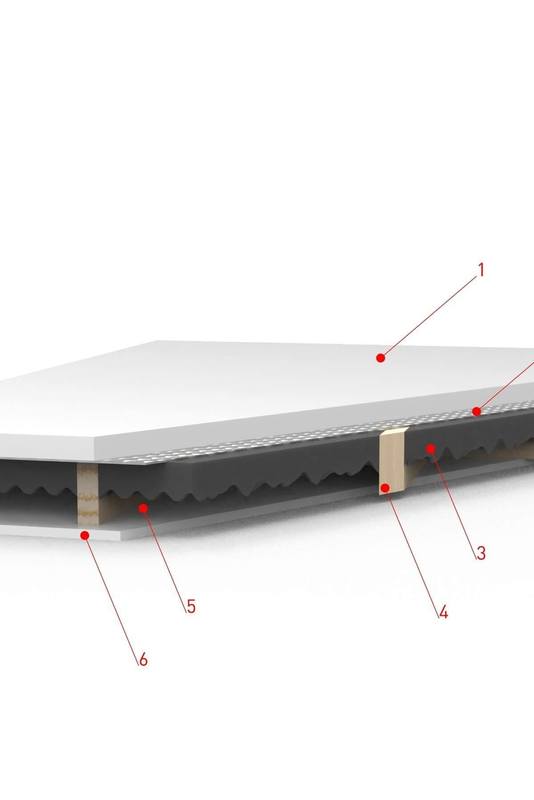

1. Befintligt tak

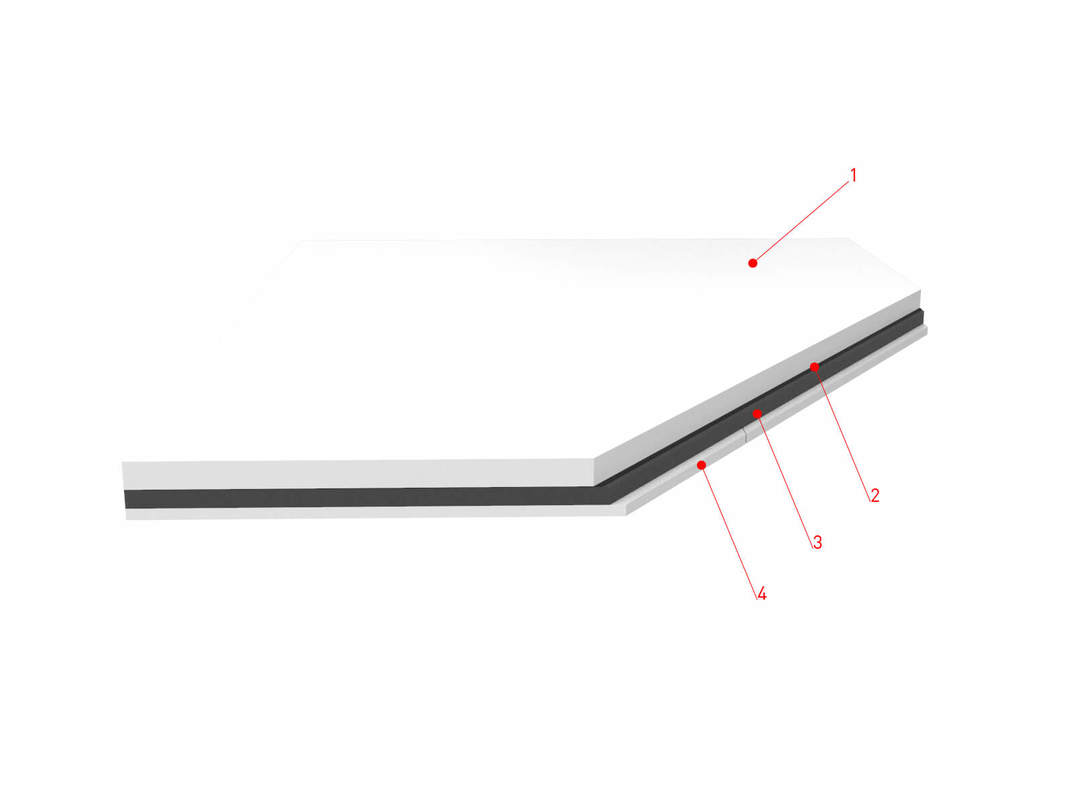

2. SilentDirect Polaric dämpmatta eller SilentDirect MLV

3. SilentDirect Egg eller SilentDirect Neo

4. Reglar

5. Luftspalt

6. Nytt tak

Steg 1 – Montering av SilentDirect Polaric dämpmatta

Börja med att montera SilentDirect Polaric dämpmatta eller MLV (siffra 2) över hela det befintliga taket eller den yta som ska ljudisoleras. För att uppnå bästa möjliga ljudisolerande effekt är det avgörande att alla skarvar tätas noggrant. Använd ett lämpligt tätningsmaterial, exempelvis tätningsmassa, för att säkerställa att inga ljudläckage uppstår.

Vi rekommenderar att du tätar skarvarna med SilentDirect Seal tätningslist, som effektivt förhindrar ljudgenomsläpp. En lämplig bredd på tätningslisten är 25–50mm, med en tjocklek på 2mm.

Steg 2 – Montering av SilentDirect Neo för optimal ljudisolering

Nästa steg är att täcka hela taket med SilentDirect Neo i 7mm tjocklek (siffra 3), direkt ovanpå den tidigare monterade SilentDirect Polaric. Syftet med detta lager är att säkerställa att de reglar som monteras i steg 3 inte kommer i direkt kontakt med det befintliga taket eller den yta som ska ljudisoleras.

För bästa effekt bör SilentDirect Neo sträcka sig ut över sidoväggarna med minst samma längd som reglarna är breda. På så sätt vilar reglarna direkt på SilentDirect Neo istället för att vidröra sidoväggarna, vilket minskar vibrationer och förbättrar ljudisoleringen ytterligare.

Budgetalternativ

Ett kostnadseffektivt alternativ är att utesluta SilentDirect Neo och istället använda SilentDirect Seal för att dämpa kontakten mellan reglarna och taket. Applicera SilentDirect Seal på baksidan, toppen och botten av varje regel innan montering. Detta minimerar ljudöverföring genom reglarna och ger en effektivare ljudisolering till en lägre kostnad. Vi rekommenderar då SilentDirect Seal 50mm bred och 4mm tjocklek.

Steg 3 – Montering av reglar för att skapa en effektiv ljudbarriär

Nu är det dags att montera reglar (siffra 4) på det befintliga taket eller den yta som ska ljudisoleras. Reglarna bör vara tillräckligt djupa för att sträcka sig minst 5cm utanför SilentDirect Neo eller SilentDirect Egg, beroende på vilken ljudisolerande produkt som används. Detta skapar en luftspalt på cirka 5cm mellan ljudisoleringen och det nya taket (siffra 6), vilket förbättrar den totala ljuddämpningen.

Val av material för det nya taket

För bästa resultat rekommenderar vi att använda minst två skivor för att skapa det nya taket:

Första lagret: OSB-skiva – Ger en stabil och skruvvänlig yta.

Andra lagret: Gipsskiva – Förbättrar ljudisoleringen genom att kombinera olika material.

Att använda olika material i flera lager är en beprövad metod inom ljudisolering, eftersom material med olika densitet hjälper till att bryta ljudvågornas spridning. Resultatet blir en tystare och mer effektivt ljuddämpad miljö.

Vikten av att undvika kontakt mellan reglar och befintligt tak

En avgörande faktor för effektiv ljudisolering är att reglarna inte får vidröra det befintliga taket eller ytan. Om reglarna ligger i direkt kontakt med taket, kommer vibrationer att överföras mellan materialen, vilket försämrar ljudisoleringen avsevärt. Genom att eliminera denna kontakt minskar ljudets vibrationer markant, vilket resulterar i en avsevärt bättre ljudisolering.

Tips 1 – Minska vibrationer mellan nya och befintliga taket

För att ytterligare minimera ljudöverföring rekommenderar vi att du applicerar SilentDirect Seal tätningslist även på framsidan av varje regel innan OSB- och gipsskivorna monteras. Detta skapar en extra barriär som minskar vibrationerna och förhindrar att det nya taket överför ljud till det befintliga taket.

Tips 2 – Fyll luftspalten med ljudabsorberande material

Innan OSB- och gipsskivorna monteras kan du förbättra ljudisoleringen genom att fylla luftspalten med ett ljudabsorberande material.

Exempel på lämpliga material är:

- Polyester

- Glasull

- Stenull

Undvik cellplast, eftersom det inte har några ljudabsorberande egenskaper. Ett kreativt och kostnadseffektivt alternativ är att använda begagnade madrasser eller andra mjuka material som effektivt dämpar ljud. Så länge materialet är ljudabsorberande kan det i princip vara vad som helst.

Steg 4 – Tätning av det nya taket

När det nya taket är monterat är det viktigt att noggrant täta runt hela konstruktionen. Detta förhindrar ljudläckage och optimerar isoleringen. Använd en tätningsmassa, även kallad fogmassa, eller ett montagelim som både kan limma och täta.

Klart! Njut av tystnaden!

Nu är ditt ljudisolerade tak färdigt – och du kan njuta av en tystare och mer behaglig inomhusmiljö.