How to soundproof a studio – A complete guide to professional sound control

Soundproofing a studio is a critical process for creating a recording environment that is free from outside noise while minimizing sound leakage to the surrounding area. A well-insulated studio ensures clean sound reproduction, better mixing, and recording without external noise affecting the result.

Unlike sound absorption, which aims to reduce reverberation and optimize the acoustics of the room, soundproofing is about creating a dense barrier that prevents sound transmission through walls, floors, ceilings, doors, and windows.

Why is soundproofing a studio important?

Sound travels through vibrations, and if a studio is not properly soundproofed, external sounds such as traffic noise, voices, or other background noise can penetrate. At the same time, high noise levels from inside the studio can spread to adjacent spaces and disturb the surrounding area.

A studio that lacks soundproofing can lead to:

- Unclear sound recording, where external sounds leak into the microphone.

- Poor mixing conditions, where outside noise affects the perception of frequencies.

- Disturbances in the surrounding area, especially when recording loud music or speech.

Solving these problems requires the right materials, construction techniques, and careful planning.

Summary – How to soundproof a studio

Creating a professional studio requires a combination of soundproofing measures to block sound in and out.

- Build sturdy walls with soundproofing panels and air gaps.

- Insulate the ceiling with vibration-damping suspensions and sound-absorbing materials.

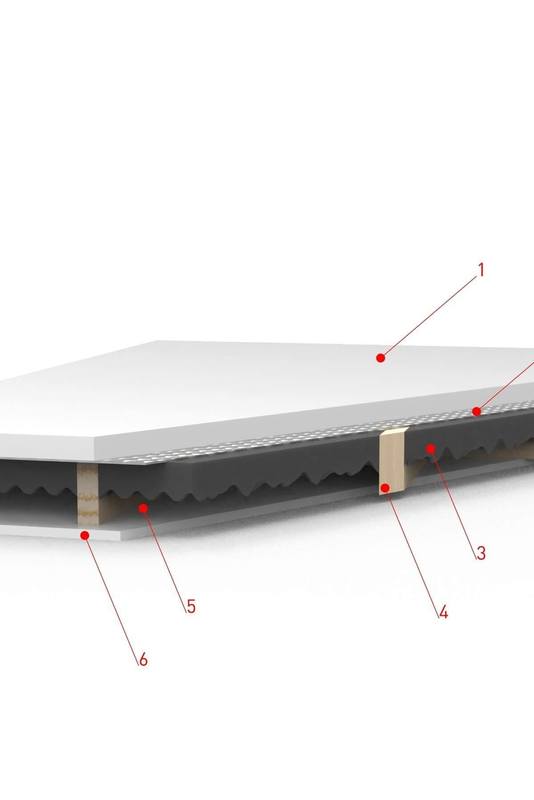

- Minimize structure-borne noise by using a floating floor and damping mats.

- Ensure that doors and windows are properly sealed with soundproofing materials.

- Secure ventilation with sound-absorbing ducts and quiet fans.

By combining these methods, you can create a soundproof studio that provides professional recording quality and an optimal working environment for music production, podcasting, or other audio projects.