Så ljudisolerar du en vägg – Lösningen på störande ljud

Att ljudisolera väggar är en effektiv metod för att minska ljudöverföring mellan rum och skapa en tystare, mer behaglig miljö. Oavsett om det handlar om bostäder, kontor eller andra utrymmen där ljudnivåerna påverkar trivsel och funktion, finns det lösningar som gör skillnad. Rätt metoder och material är avgörande för att uppnå optimal ljudisolering – och för att lösa dina akustiska utmaningar.

Vad innebär ljudisolering av väggar?

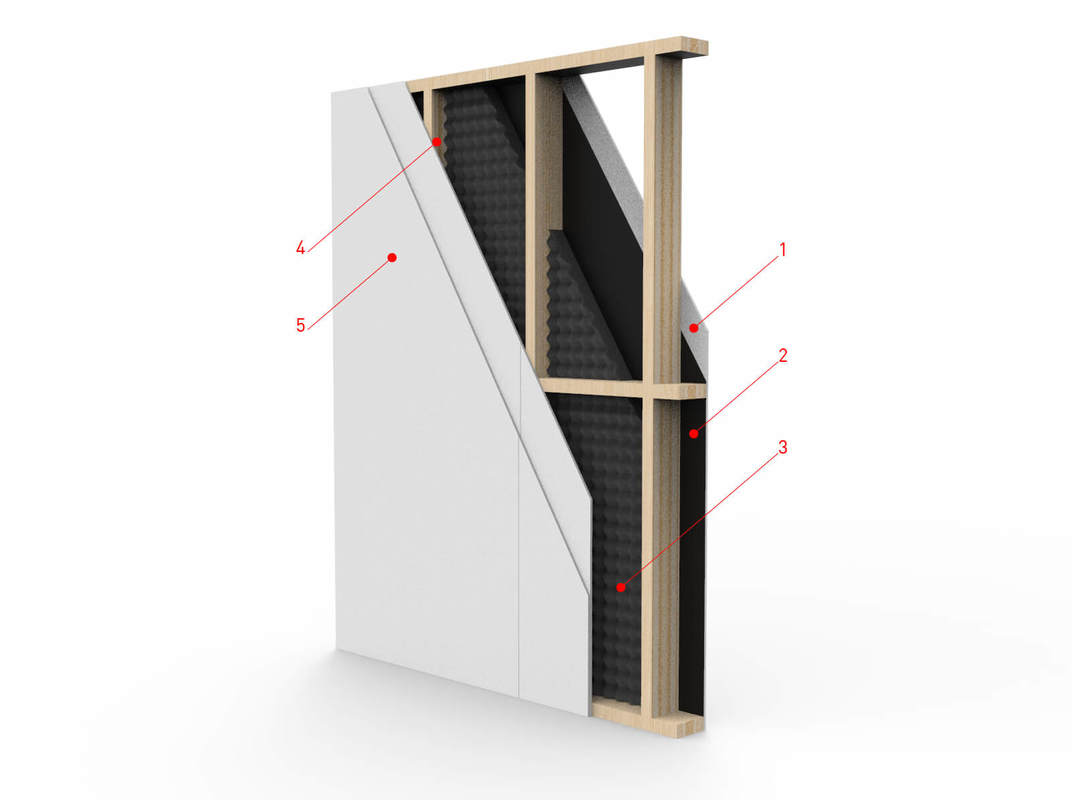

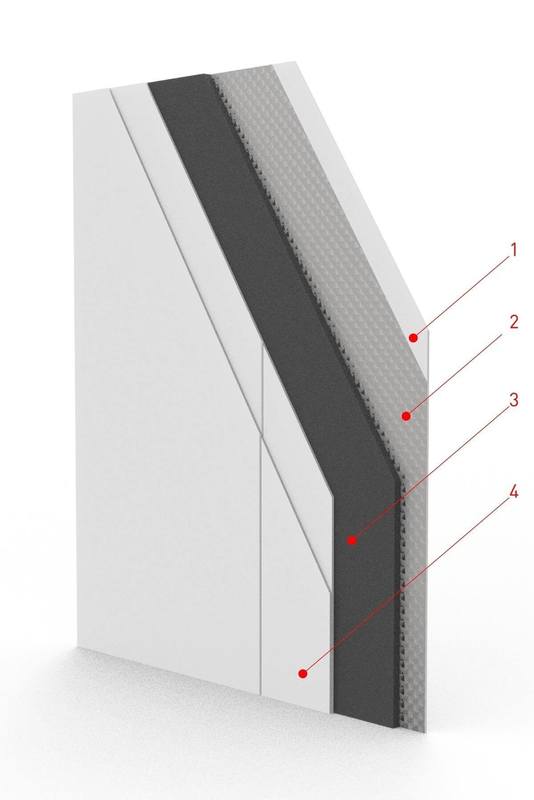

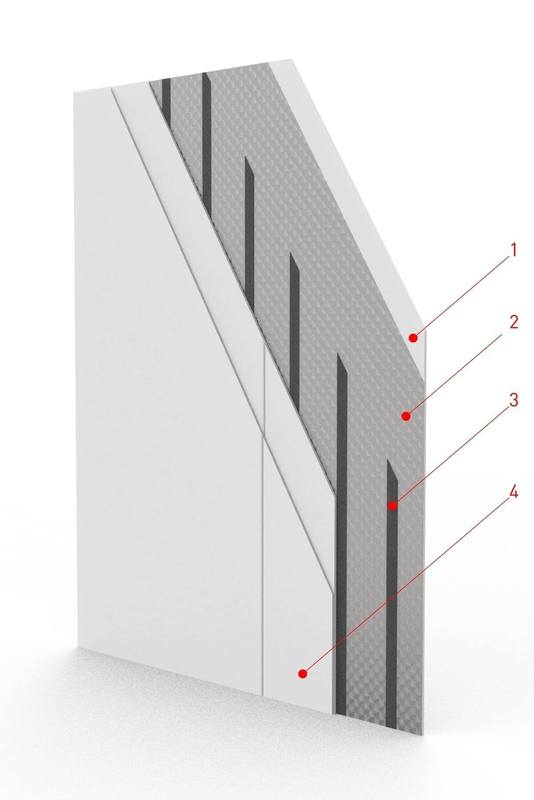

Ljudisolering av en vägg innebär att förhindra att ljud tränger igenom från en sida till den andra. Detta görs genom att bryta ljudets väg med hjälp av tyngre material, skapa luftspalter som dämpar ljudvågor och använda ljudabsorberande produkter som akustikskum eller mineralull. Denna kombination av tekniker blockerar effektivt både höga och låga frekvenser, vilket gör den till en lösning för alla typer av ljudproblem.

Problemen ljudisolering löser

Störande ljud kan påverka allt från arbetsmiljöer till hemkomfort. Här är några exempel på hur ljudisolering kan förbättra vardagen:

Minskad ljudöverföring

Reducera ljudet mellan rum, vilket är särskilt viktigt i bostäder med tunna väggar eller flerfamiljshus.

Ökad integritet

Förhindra att privata samtal eller aktiviteter sprider sig till andra delar av hemmet.

Bättre akustik

Minska ekon och ljudreflektioner, särskilt i rum som studios eller hemmabiosystem.

Förbättrad arbetsmiljö

Skapa en tyst arbetsplats fri från distraktioner, oavsett om det är ett hemmakontor eller en kommersiell arbetsmiljö.

Skydd mot yttre buller

Blockera trafikljud, grannaktiviteter eller andra externa störningar.

Förbättrad sömnkvalitet

Ljudisolerade väggar kan skapa en rofylld sovrumsmiljö, fri från ovälkomna ljud.

Varför är ljudisolering viktigt i olika miljöer?

Ljudproblem uppstår i många olika miljöer, och ljudisolering av väggar är en mångsidig lösning. Här är några exempel:

Hem

Ljudisolering ger lugn och ro i sovrum, vardagsrum och hemmabiorum.

Kontor

Förbättra koncentrationen och minska bakgrundsljud i öppna kontorslandskap eller mötesrum.

Restauranger och hotell

Höj komforten för gäster genom att minimera störande ljud mellan rum eller matsalar.

Studios och biografer

Skapa en optimal akustisk miljö för inspelning eller underhållning.

Offentliga utrymmen

Förbättra ljudmiljön i skolor, bibliotek och vårdinrättningar där buller kan påverka trivseln.

Så här fungerar våra lösningar

Vi erbjuder produkter som är utvecklade för att leverera maximala resultat i ljudisolering. Våra material är inte bara högpresterande utan också estetiskt tilltalande och hållbara. Oavsett om du vill minska ljudnivåerna i hemmet eller optimera akustiken på arbetsplatsen, kan vi erbjuda lösningar som matchar dina behov. Produkterna är enkla att installera och designade för att passa in i alla typer av utrymmen, från moderna bostäder till industriella miljöer.

Ta steget mot en tystare miljö

Ljudisolering av väggar är nyckeln till att skapa en mer trivsam och funktionell miljö, där störande ljud inte längre är ett problem. Utforska våra produkter och lösningar för att hitta rätt alternativ för dina behov. Genom att välja våra ljudabsorberande och ljudisolerande material får du en långsiktig och effektiv lösning för en tystare vardag.